A factory prepared blend of carefully selected raw materials, Portland cement and graded fillers, it is designed for use with water and aggregates to produce high strength, water retaining and self curing screed for interior and exterior floor applications. It meets and exceeds the requirements of National and International Standards.

Features & Benefits

- High strength

- Shock and impact resistant

- Water retaining, self curing

- No shrinkage, No cracks

Product Details

Packaging

25kg Bag

Coverage

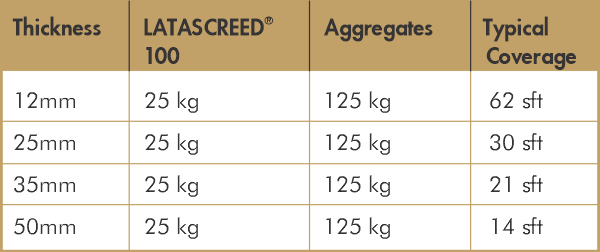

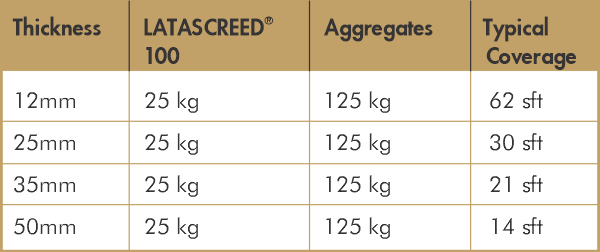

Coverage will be based on following mix design. the grain size matrix has to be uniformly distributed up to a size of 8 mm.

(Minimum thickness: 12 mm; Maximum thickness: 70 mm)

Typical coverage with 1:5 mix by weight

Coverage

Coverage will be based on following mix design. the grain size matrix has to be uniformly distributed up to a size of 8 mm.

(Minimum thickness: 12 mm; Maximum thickness: 70 mm)

Typical coverage with 1:5 mix by weight

Coverage

Coverage will be based on following mix design. the grain size matrix has to be uniformly distributed up to a size of 8 mm.

(Minimum thickness: 12 mm; Maximum thickness: 70 mm)

Typical coverage with 1:5 mix by weight

Coverage

Coverage will be based on following mix design. the grain size matrix has to be uniformly distributed up to a size of 8 mm.

(Minimum thickness: 12 mm; Maximum thickness: 70 mm)

Typical coverage with 1:5 mix by weight

- Use aggregates of larger size (up to 12 mm) for screed thickness more than 70 mm and upto 120 mm

- Approximately 8 to 10 ltrs. of water is required for an ideal mix. Adjust the water content depending on the site conditions.

- For wet on wet system, Slurry Bond Adhesive SBA 20 is recommended

- As an alternative LATASCREED® 100 mixed with water can also be used as slurry

- For wet on dry system, a suitable thinset adhesive from MYK LATICRETE range can be used to install tiles

- EN 13813, Designation CT-C25F3B1.5SH40

- VOC: Nil

How to apply

Substrate:

All surfaces should be structurally sound, clean and free of all dirt, oil, grease, curing compounds etc. Dry, dusty concrete surface or masonry should be dampened and excess water swept off. Installation may be made on a damp surface. If the concrete or masonry surface is very old, apply a slurry bond coat of LATICRETE® 111, filler powder mixed with LATICRETE® 3642 diluted with water in the ratio of 1:3, prior to installation of mortar bed.

Surface Preparation:

- If a plaster/leveling render is applied, ensure that it is cured for at least 7 days to achieve proper strength before application of tile adhesive for installation of tile

- Ensure the substrate is clean and free from impurities like dust, dirt, debris, oil, grease, curing agents, loose plaster etc.

- Dampen the surface before application of thin-set adhesive

- Clean the back of tile for removal of any dust or coating.

- Mix LATASCREED 100 with potable water in the desired ratio ie 1:2 in a clean container (For priming of the surface of concrete)

- Mix LATASCREED 100, engineered cement and well graded clean sand in a ratio of 1:4.

- Add the powder mix to the water and mix slowly, adjust the mix to a semi-dry consistency.

- Apply the prime coat of LATASCREED 100 and place the mortar while the slurry bond coat is still wet and tacky.

- Compact the surface of the mortar with a flat trowel and ensure all voids are filled.

- Level the mortar true and plumb to carry out the next stage of installation with a thin set adhesive.

- Wait 36 hours for the mortar to set and cure before starting the waterproofing or installation of Natural stones using a thin set adhesive.

- Useful as the leveling bed before installation of natural stones and all varieties of tiles

- Makes the tile or stone bedding moisture-free, so that absorbent natural stones do not develop stains

- Recommended for interior and exterior applications

- Concrete

- Cement Mortar Beds (compressive strength>25 Mpa)

- Cement Terrazzo